After 15 years of professional printing and packaging production, our company has learned from past experience and summarized a complete quality control management system that is suitable for our own development and meets the quality standards of the packaging industry, including:

- Basic standards for IQC incoming material inspection.

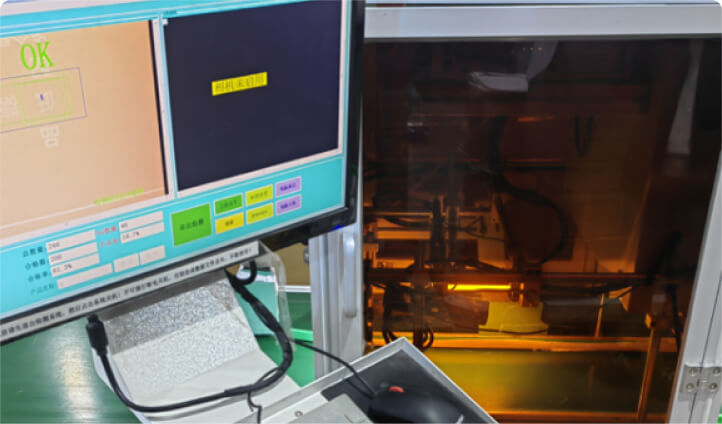

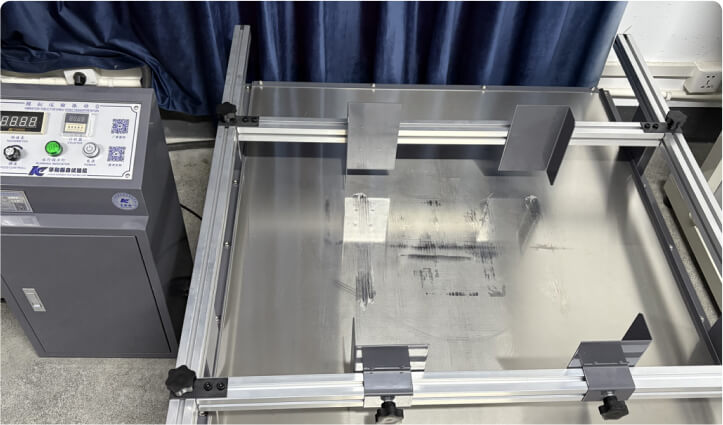

- Basic standards for IPQC process quality control.

- Basic standards for FQC inspection.

- OQC sampling quality inspection standards.

- We have a clear quality management flow chart.

- We have formed complete quality control standards for key workstations.

- In accordance with ISO9001 quality management system and international quality inspection standard GB/T2828.1-2012.

- We have complete quality control standards for each category of packaging products. For example, color box quality standard book, premium box quality standard book and folding box quality control standard book, etc.

In addition, we will form a complete set of quality control documents and quality inspection standards for different types of products that are confirmed and accepted by the customer during the sample production process and before formal order mass production in accordance with the customer's quality requirements and through timely communication with the customer.